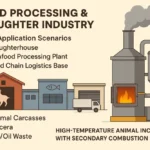

High-Temperature Animal Incinerators for the Food Processing & Slaughter Industry

In regions from Southeast Asia (Vietnam, Thailand) to East Africa (Kenya, Uganda) and South America (Brazil, Colombia) the food processing and slaughter sectors generate significant waste streams. For large-scale operations such as a major slaughterhouse, seafood processing plant, or a cold-chain logistics base, effective disposal of animal by-products is critical.

The specialist solution from HICLOVER ― the high-temperature animal incinerator with secondary combustion system ― is designed specifically for handling waste types including animal carcasses, offal, and fat/oil waste generated by food processing and slaughtering operations.

Key Application Scenarios

-

A beef or poultry slaughterhouse in a Brazilian export zone disposing of large volumes of carcasses and off-cuts.

-

A seafood processing plant in coastal Thailand managing fish frames, shells, internal organs, and fat residues during peak season.

-

A cold-chain logistics hub in Kenya that receives animal-derived products and requires on-site disposal of spoiled or unusable items (oils, fat waste, carcasses).

Why the HICLOVER Dual-Combustion Incinerator Works

-

The dual-combustion (primary chamber + secondary after-burn) ensures complete destruction of organic material and fat/oil waste with minimal smoke and residual odor. (clover-incinerator.com)

-

High internal temperatures and refractory lining handle heavy-duty waste streams such as animal carcasses and viscous fat/oil residues. The manufacturer describes dual-chamber structure as standard. (clover-incinerator.com)

-

By deploying a system specifically for the food-processing/slaughter industry you address regulatory compliance, biosecurity risks (carcass disposal), and environmental concerns (oil/fat waste) in one.

-

Suitable for integration in large plants where waste generation is continuous; compatibility with diesel, LPG, or natural gas burners allows flexibility in region-specific fuel availability.

Practical Implementation Considerations

-

The incinerator should be located in a designated disposal zone within the processing complex, ideally adjacent to the waste feed stream of carcasses/offal.

-

Ensure the system’s feed capacity and burning rate match the volume of waste: e.g., a large slaughterhouse processing several tons per day may require an incinerator capable of 200 kg/hour or more feed rate.

-

Consider downstream air-emission treatment (scrubber, bag-filter) if regional regulation demands it (especially fat/oil fumes).

-

Train operators on handling high-fat waste (which may produce more smoke if fed cold) and ensure refractory chamber maintenance to sustain high-temperature performance.

-

Schedule regular inspections of ash residues and chamber integrity because fat/oil waste can accelerate wear if incineration is not complete.

Environmental & Operational Benefits

-

Reduces risk of disease transmission by disposing of animal carcasses in a controlled high-temperature environment rather than burying or uncontrolled burning.

-

Combines disposal of offal, fat/oil waste, and carcass material in one dedicated incinerator rather than using multiple disposal methods.

-

Supports the circular economy in processing plants by simplifying waste-stream management and freeing space that might otherwise be used for temporary storage or decaying waste.

-

Enhances corporate and regulatory credentials: operating a purpose-built high-temperature animal incinerator sends a clear signal of compliance and environmental responsibility.

SEO Keywords & External Links

For SEO optimisation please include internal/external link references to HICLOVER:

-

HICLOVER animal incinerator (link to homepage)

Conclusion

In large-scale food-processing and slaughter-industry contexts ― whether in Brazil, Thailand, Kenya or beyond ― the disposal of animal carcasses, offal and fat/oil waste presents a complex challenge. By installing a high-temperature animal incinerator with secondary combustion from HICLOVER, operators gain a reliable, efficient, and regulation-friendly solution tailored to this waste stream.

2025-11-01/22:59:22

|

Incinerator Items/Model |

HICLOVER TS100(PLC)

|

|

Burn Rate (Average) |

100kg/hour |

|

Feed Capacity(Average) |

150kg/feeding |

|

Control Mode |

PLC Automatic |

|

Intelligent Sensor |

Continuously Feeding with Worker Protection |

|

High Temperature Retention(HTR) |

Yes (Adjustable) |

|

Intelligent Save Fuel Function |

Yes |

|

Primary Combustion Chamber |

1200Liters(1.2m3) |

|

Internal Dimensions |

120x100x100cm |

|

Secondary Chamber |

600L |

|

Smoke Filter Chamber |

Yes |

|

Feed Mode |

Manual |

|

Burner Type |

Italy Brand |

|

Temperature Monitor |

Yes |

|

Temperature Thermometer |

Corundum Probe Tube, 1400℃Rate. |

|

Temperature Protection |

Yes |

|

Automatic Cooling |

Yes |

|

Automatic False Alarm |

Yes |

|

Automatic Protection Operator(APO) |

Yes |

|

Time Setting |

Yes |

|

Progress Display Bar |

3.7 in” LCD Screen |

|

Oil Tank |

200L |

|

Chimney Type |

Stainless Steel 304 |

|

1st. Chamber Temperature |

800℃–1000℃ |

|

2nd. Chamber Temperature |

1000℃-1300℃ |

|

Residency Time |

2.0 Sec. |

|

Gross Weight |

7000kg |

|

External Dimensions |

270x170x190cm(Incinerator Main Body) |

|

Burner operation |

Automatic On/Off |

|

Dry Scrubber |

Optional |

|

Wet Scrubber |

Optional |

|

Top Loading Door |

Optional |

|

Asbestos Mercury Material |

None |

|

Heat Heart Technology(HHT) |

Optional |

|

Dual Fuel Type(Oil&Gas) |

Optional |

|

Dual Control Mode(Manual/Automatic) |

Optional |

|

Temperature Record |

Optional |

|

Enhanced Temperature Thermometer |

Optional |

|

Incinerator Operator PPE Kits |

Optional |

|

Backup Spare Parts Kits |

Optional |

|

Mobile Type |

Optional:Containerized/Trailer/Sledge Optional |